JRC's award-winning Advanced Perforating Flow Laboratory houses multiple leading-edge testing vessels with inflow monitoring and evaluation technologies, allowing the study of deviated and horizontal completions, high- and ultrahigh-temperature reservoirs, high- and ultrahigh-pressure reservoirs, unconsolidated reservoirs, oil and gas reservoirs, extreme pressure differentials, and chemical intervention treatments. No other facility in the world comes close to the advanced capabilities of JRC’s APFL.

Conventional API RP19B Section II & IV testing uses nominal confining pressures. Using the full capabilities of the Advanced Perforating Flow Laboratory (APFL) at Jet Research Center, perforator performance can now be simulated at exact downhole conditions, matching true reservoir and wellbore pressures, confinement stress, perforation orientation, and wellbore temperature. The capabilities of our advanced testing vessels, testing techniques, and instrumentation are truly unmatched within the oil and gas industry. Our advanced vessel capabilities include:

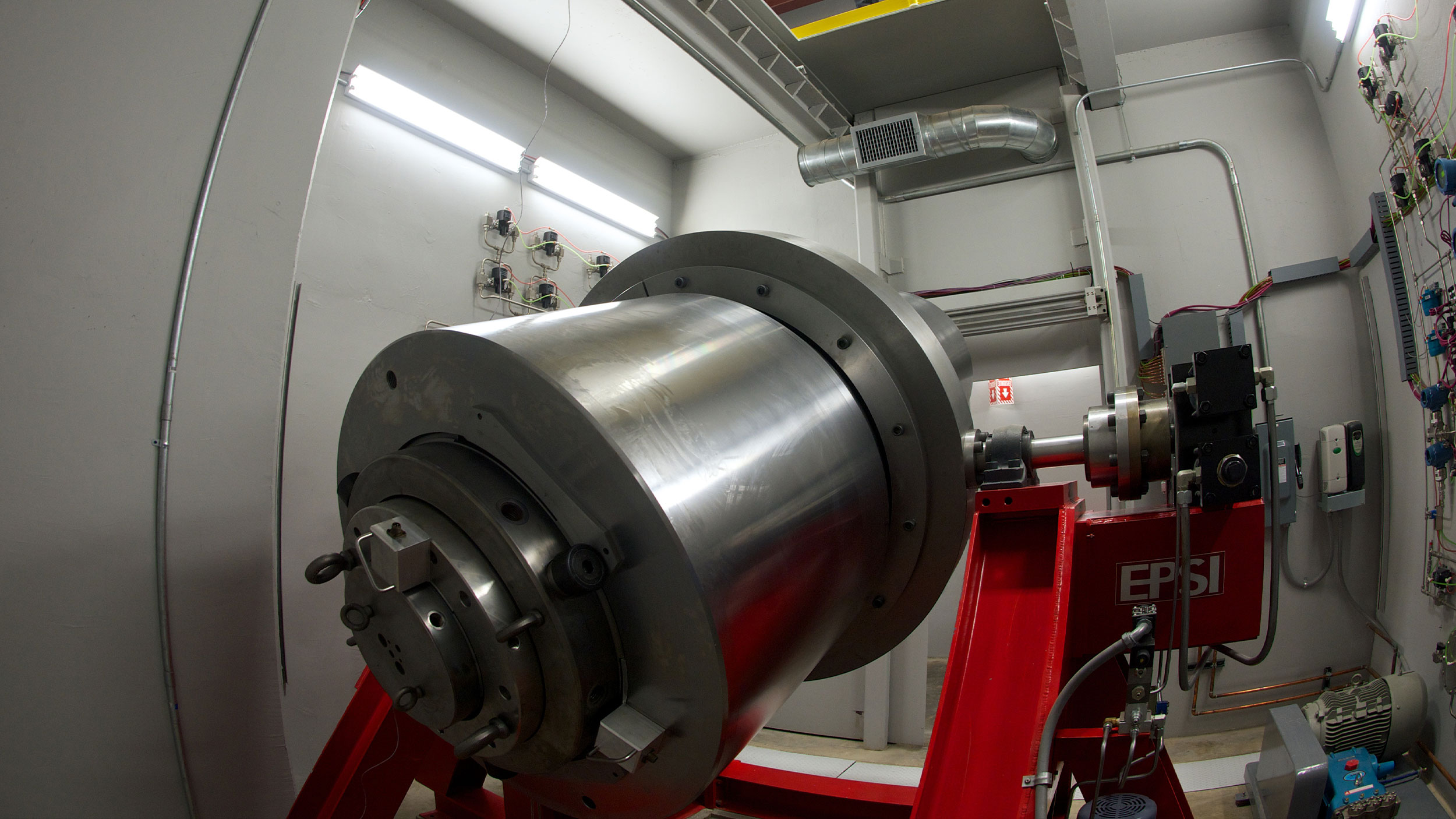

Rotating Perforations

High Pressure/Ultra-high Temperature

Ultra-high Pressure

Plus testing is an advancement to traditional API RP19B Section II testing. It is a collaborative effort between JRC’s APFL team, our clients’ needs, and the specific perforating scenario. These tests are designed to control the dynamic pressure response to better match the wellbore-pressure transients created during perforating. Through better testing and evaluation of dynamic underbalance/overbalance pressures, these tests can help identify the optimum perforating system and evaluate how dynamic pressures can significantly influence perforation-tunnel geometry, resulting in enhanced production.

Advanced core scanning allows unmatched inflow analysis and provides advanced understanding of perforation-tunnel geometry and potential flow profile. This technology can also be useful for component and material investigation and for critical quality control.