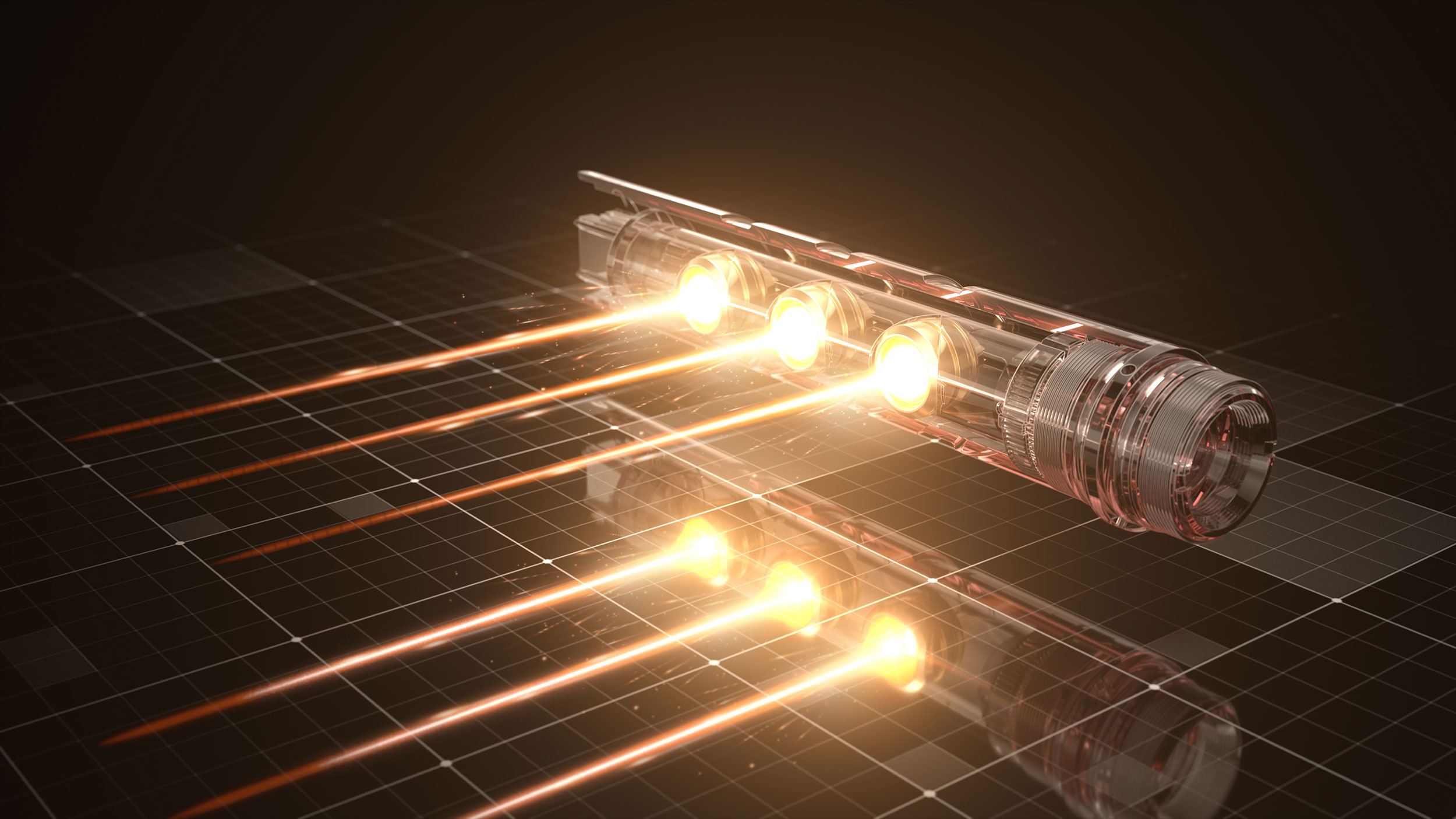

In an unconventional completion, it is important to utilize as many of the open perforations as possible to optimize fluid and proppant placement in a formation. Data suggests that orienting all perforations along the same azimuth in the casing helps to ensure that perforations are as uniform as possible, making the treatment more effective. For high-volume, high-efficiency applications, such as orienting perforations in non-fiber-optic wells, the Velocity Aligned gun system provides an economic option for orienting perforations in 2.5° increments around the casing circumference. This accurate and efficient system is fully adjustable at the wellsite.

No orienting subs or lock-rings

Compatible with all industry standard charges

Reduction in make-up length

Adjustable in 2.5° increments

| Velocity Aligned | Competing Systems | Benefits of Velocity Aligned Systems |

| Charge tube aligned, instead of gun carrier | Reliance on external lock rings and subs |

|

| Modular platform | Requires loading, assembly, and/or wiring on location |

|

| Optimized length and weight | Needs longer guns and additional hardware |

|

| Multiple perforation charge specifications | Often limited to a single perforation charge specification |

|